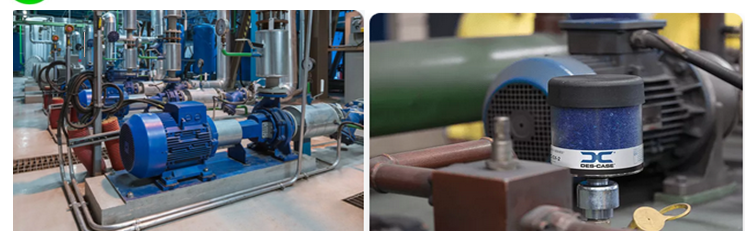

Machines are the key assets for an industrial plant, lubricant is the life blood of any oil wetted machinery and the cost of replacing failed equipment due to wear or lube related problems is very expensive. Extending oil and machine life is crucial in maximizing production uptime, profit and reduce maintenance cost of equipment. O-SECUL Nigeria Limited in collaboration with its strategic partner DES-CASE Corporation have been supporting different sectors of the Nigerian Economy in increasing machinery uptime and profit by providing technical solutions and sales of instruments.

SEVEN WAYS CONTAMINANTS CAN GET INTO YOUR MACHINE AND HOW TO AVOID THEM.

If particles are the root cause of most of the wear occurring in machines, organizations should work to control particle ingression and removal. Did you know that 82% of mechanical wear is caused by particle contamination? Fight back against contamination and unnecessary downtime by examining and avoiding the seven ways contaminants get in your machines.

WHAT IS LUBE ROOM AND WHY IS IT IMPORTANT?

A lube room is just what it sounds like: a room or area in a facility where lubricant is stored. But in order for your plant’s lube room to help you achieve your reliability goals, you need to know more than that.

Once your oil is filtered to the correct level, the battle to keep it that way begins immediately. One overlooked source of contamination is storing oil in the wrong place. Space inside a facility is often at a premium, but when you store oil outside, changes in surrounding temperature cause air to enter and exit the drum—and with it, moisture. If the drum is uncovered, dirt can settle on it, and small particles can enter the drum along with the air.

Move oil storage to a custom designed Lubrication Storage & Handling Room, the lubricant’s sanctuary from a harsh plant environment. The “Lube Room” provides a dedicated storage area where lubricants can be adequately prepared and maintained for service.

A GUIDE TO OIL FLTRATION

Everyone is interested in extending life…and a company’s equipment is no exception. While our equipment won’t last forever, more and more companies are looking for processes and products that will help keep them up and running. Reduced downtime, increased lubricant life, less recycling and repair cost are becoming more important than ever as the industry moves to the next level.

Maintaining clean oil is one of the best investments a company can make, yet contamination often remains an overlooked factor behind premature machinery failure and diminished lubricant life. With the cost of oil, increased desire to minimize usage and waste, and the need to prolong the life of equipment, the economic case for protection—from the time oil enters a facility until it leaves—is stronger than ever.